The engineers compose the bulk of our club. They deal with all aspects of building the car, and make sure it runs. The engineers are split into two main teams, mechanical and electrical. They are led by the Chief Mechanical Engineer and Chief Electrical Engineer, respectively.

Mechanical

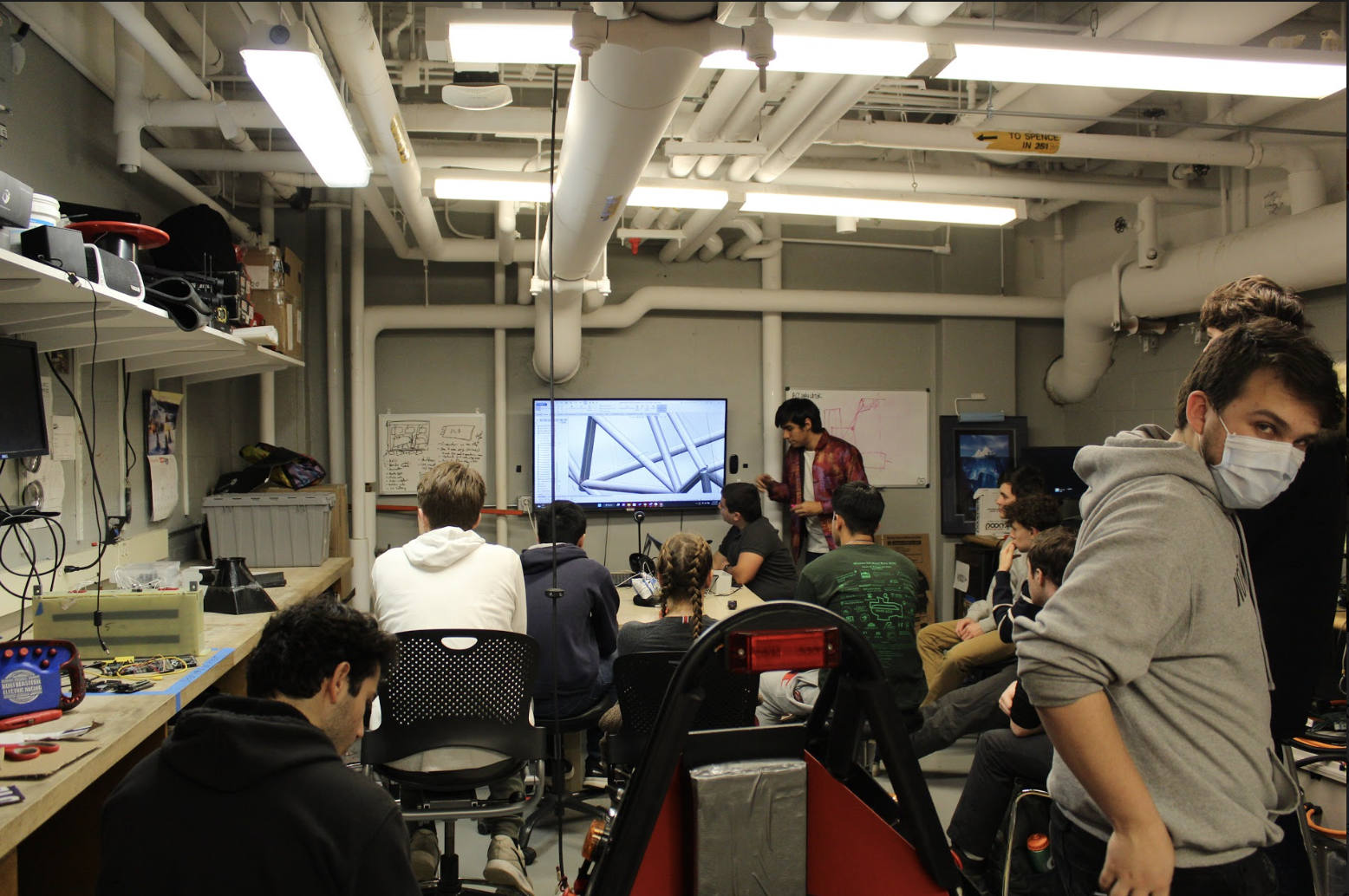

The mechanical side of engineering is involved with the mechanical research, design, and manufacturing of the car. This subteam is split into four systems: Handling, Drivetrain, Ergonomics, and Structural. Projects typically start in the research stage, then go through concept sketching, and finally get turned into detailed Computer Aided Designs (CAD) models in Solidworks. Throughout the design process, calculations and simulations are used to validate design decisions and ensure components are staying in compliance with the competition rules. Once the design process is completed, the team moves to the machine shop where the components are fabricating using tools such as mills, lathes, CNC machines, and hand tools, and later installed into the car via welding and bolted assemblies.

Electrical

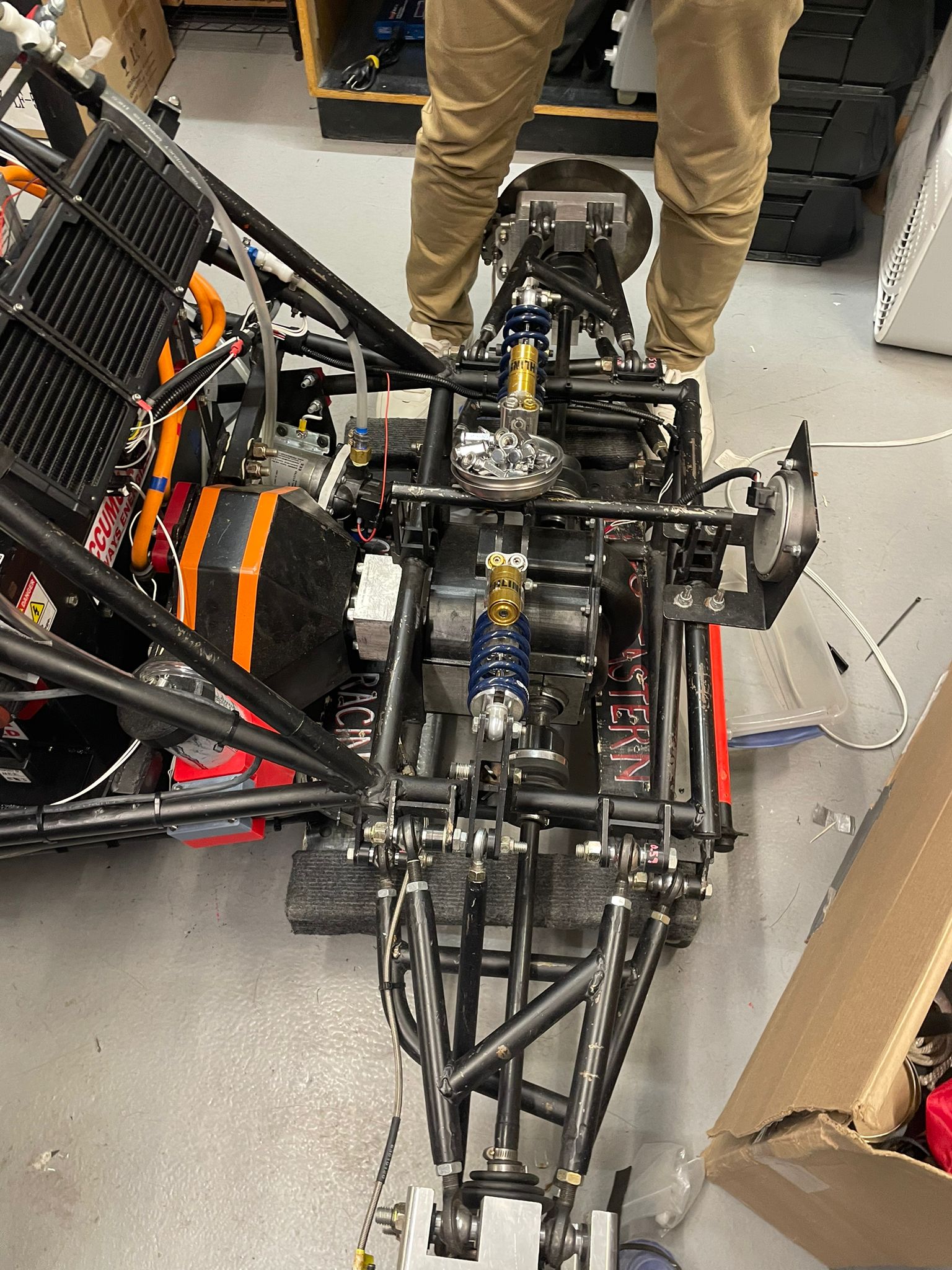

On the electrical side of engineering, the team works with power electronics, low voltage circuitry, printed circuit boards, controller area networks, telemetry, and more. The subteam is split into three system: Tractive, Low Voltage, and Data & Controls. Electrical-based projects also follow a design process in which they are first designed, then fabricated and tested, and finally installed into the car. Team members who engage with electrical work handle everything electrical (and computer) related including the custom accumulator, tractive systems, LV circuits (safety, controls, etc.), and telemetry system.

2023 System Spotlight:

Tractive

The Tractive team is responsible fort he high-power electronics on our car, making the car move! This encompasses everything from designing the batteries to the motor. Tractive members spend around 10 hours a week working on the car. Handling hihg voltage and lithium batteries demands precision and safety precautions to protect team members; safety has to be paramount. The team uses Slack to stay in touch, and uses both Confluence and FinishLine to keep track of their projects, making sure they’re done on time.

Zach Perry, our tractive team’s head, says his favorite part of the system is that its a great place to meet like-minded people with the same enthusiasm for electric racing as him. His favorite memory with the team is of his first competition with us, when we passed technical checks and placed in the top three! Looking ahead, the team is excited to see our new car hit the road, a tangible reminder of the dedication and teamwork that define NER.

Left: Part of the car’s tractive systems. Right: Zach Perry, head of NER’s tractive team, in the driver’s seat.